CNC molds play a crucial role in modern manufacturing, enabling precision and efficiency. But what exactly is a CNC mold, and why is it so important? CNC, or Computer Numerical Control, is a technology that revolutionizes the way molds are created, ensuring high accuracy and repeatability. In this post, we'll dive into the CNC mold-making process, its benefits, and its applications across various industries. By the end, you'll understand why CNC molds are a game-changer in today's production world.

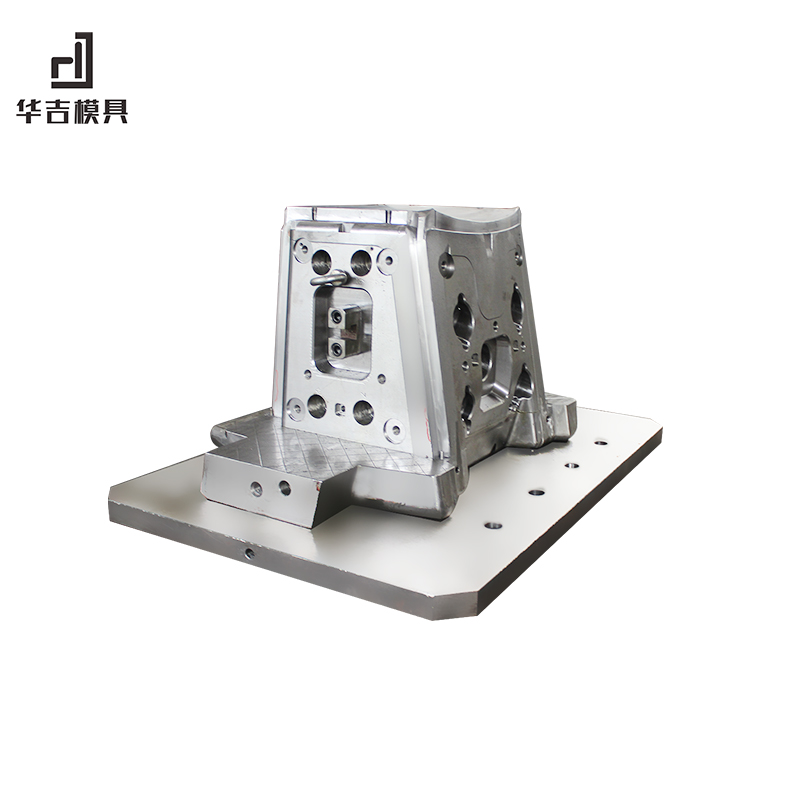

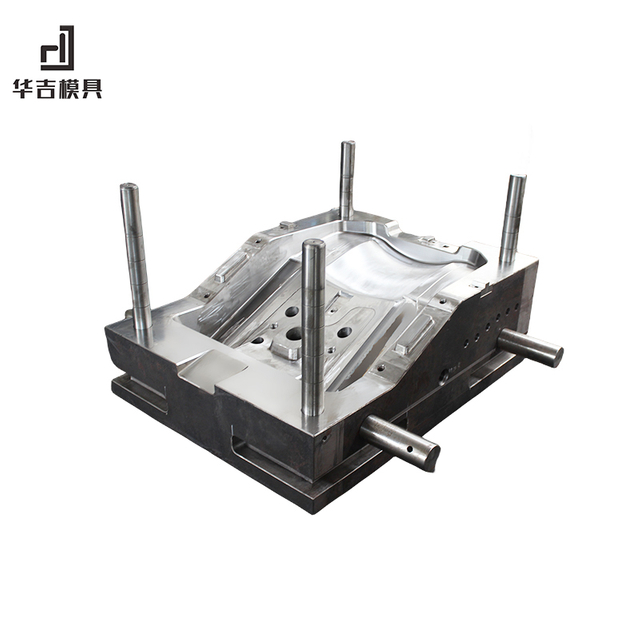

A CNC mold is a mold created using Computer Numerical Control (CNC) technology. This process involves the use of computer-driven machinery to shape and cut materials with high precision. The CNC system allows for automated control of tools like mills, lathes, and routers, enabling accurate mold production for various industries, such as automotive, consumer goods, and medical devices.

CNC molds are different from traditional molds in several ways. While traditional mold-making often involves manual processes or less precise machinery, CNC technology automates the shaping process, which reduces human error and ensures consistency across multiple molds. Traditional methods can be slower and less precise, especially for complex mold designs.

Creating a CNC mold typically involves several key steps:

1. Design: First, a 3D model of the desired mold is created using CAD (Computer-Aided Design) software. This model includes all the detailed features needed, such as cavities, cores, and ejection systems.

2. Programming: The 3D model is then converted into a set of instructions that tell the CNC machine exactly how to shape the mold. CAM (Computer-Aided Manufacturing) software plays a crucial role here.

3. Machining: The CNC machine begins cutting the material, which could be steel, aluminum, or other alloys. This step involves rough cutting to remove excess material, followed by finishing cuts to achieve the final shape and smooth surface.

4. Polishing and Inspection: Once the mold is shaped, it is polished to ensure a smooth surface. Precision inspection ensures the mold meets all required specifications, including size, surface finish, and overall functionality.

Common materials used in CNC mold making include:

Material | Advantages | Applications |

Steel | Durable, high resistance to wear and heat | High-volume production, injection molds |

Aluminum | Lightweight, good thermal conductivity | Low-volume molds, quick heat dissipation |

Beryllium Copper | Excellent thermal conductivity, durable | Molds requiring precise temperature control |

Titanium | Strong, corrosion-resistant | High-performance, aerospace, and medical molds |

Precision is critical in CNC molding, as even the smallest error can result in defects in the final product. CNC machines allow for the creation of molds with extremely tight tolerances, ensuring that parts produced from these molds fit together perfectly and perform as intended. In industries like automotive and medical devices, where accuracy is paramount, CNC molds offer a significant advantage over traditional mold-making methods. The automation of the CNC process also minimizes human error and speeds up production times, contributing to overall cost savings and efficiency.

CNC technology plays a key role in ensuring consistent and high-quality mold production. Unlike traditional methods, where human error and manual adjustments can affect the final product, CNC machines operate with precise, computer-controlled movements. This ensures that every mold produced is identical, down to the smallest detail. The high precision of CNC molds is especially important for industries like automotive and medical device manufacturing, where even minor deviations can lead to defective products.

The repeatability of CNC machining further enhances its appeal for mass production. Once a mold design is programmed, the CNC machine can produce thousands of identical parts with minimal variation. This consistency is a significant advantage over traditional methods, where each mold might require adjustments and recalibrations, leading to potential quality control issues.

One of the primary benefits of CNC molds is the speed at which they are produced. CNC machines can work continuously, 24/7, without the need for breaks or supervision. This results in faster production cycles compared to traditional mold-making methods, where manual processes often slow down the overall production time. Additionally, CNC machines can handle multiple processes simultaneously, such as milling, turning, and drilling, further accelerating the production process.

Another advantage of CNC technology is the reduction in setup time. Traditional mold-making methods often require lengthy setup periods, especially when switching between different mold designs. In contrast, CNC machines can be easily reprogrammed for different designs, which reduces the time spent on setup and increases throughput. This leads to more efficient production processes, ultimately lowering costs and improving turnaround times for customers.

CNC mold-making offers significant advantages when it comes to customization and flexibility. The ability to create complex geometries with ease is one of the defining features of CNC technology. Traditional molds often require extensive hand-finishing to achieve intricate details or specific features. However, with CNC, these shapes and details can be directly programmed into the machine, ensuring precision and consistency.

Moreover, CNC molds allow for quick modifications during design changes. In traditional mold-making, making design changes can be a time-consuming and costly process, requiring significant rework. With CNC technology, adjustments to the mold design can be made quickly by reprogramming the machine, which helps keep projects on schedule and within budget. This flexibility makes CNC molds ideal for industries where product designs are frequently updated or where short production runs are required.

Benefit | CNC Molds | Traditional Molds |

Precision | High precision, minimal variation | Higher risk of human error |

Repeatability | Identical molds, consistent quality | Inconsistent results |

Speed | Faster production cycles | Slower production |

Customization | Complex geometries, easy modifications | Limited customization |

Efficiency | Reduced setup time, continuous operation | Longer setup, more downtime |

CNC molds bring speed, flexibility, and high precision to industries that require consistent, high-quality molds, providing a clear advantage over traditional methods.

CNC molds play a vital role in the automotive industry by ensuring the precise manufacturing of various automotive components. These molds are used to produce parts that require high accuracy, such as engine components, body panels, and trim pieces. With the help of CNC technology, automotive manufacturers can produce molds that meet the stringent quality standards required for mass production.

Examples of automotive components made using CNC molds include dashboard parts, door handles, bumpers, and interior trim. These components are often made from durable materials like plastic and metal, which require molds capable of withstanding high pressures and temperatures. CNC molds are perfect for this, as they offer precise geometries and ensure uniformity across thousands of parts.

In the consumer goods industry, CNC molds are frequently used to produce everyday items like containers, kitchen appliances, and household items. High-volume manufacturing requires molds that can produce large quantities of parts consistently and with minimal defects. CNC molds are especially useful in this area because they can produce complex designs that meet both functional and aesthetic requirements.

One of the biggest advantages of using CNC molds in consumer goods manufacturing is their ability to reduce production costs. Since CNC machines operate with high precision, they minimize the need for rework and reduce waste. This is crucial for companies that produce high-volume, low-cost items, such as plastic bottles, packaging materials, and electronic components. CNC molds allow for faster production cycles, keeping costs low while maintaining quality.

Precision is of utmost importance in the medical and aerospace industries, where even the smallest deviation can have serious consequences. CNC molds are used extensively in these industries to produce parts that must meet rigorous safety and performance standards. Medical devices, such as surgical tools, implants, and diagnostic equipment, require CNC molds that ensure consistent quality and safety.

In the aerospace sector, CNC molds are used to manufacture critical components such as engine parts, fasteners, and structural elements. These parts must be lightweight yet durable, and CNC molds provide the necessary precision and material control to meet these demands. The ability of CNC molds to handle complex geometries and provide tight tolerances is essential for ensuring that aerospace components perform as required in high-stress environments.

Industry | Applications | Benefits of CNC Molds |

Automotive | Engine components, bumpers, dashboard parts | High precision, mass production efficiency |

Consumer Goods | Containers, kitchen appliances, household items | Low-cost, high-volume production, complex designs |

Medical | Surgical tools, implants, diagnostic devices | High precision, safety, and performance reliability |

Aerospace | Engine parts, fasteners, structural components | Lightweight, durable, and precise components |

Tip: In these industries, CNC molds ensure that products are manufactured to exact specifications, meeting the high standards of safety, reliability, and functionality that are essential in critical applications.

Choosing the right material for CNC molds is one of the most crucial decisions in the mold-making process. The material affects not only the mold’s longevity but also its performance and the quality of the final product. Steel, stainless steel, aluminum, and other alloys are commonly used materials, but each has its strengths and weaknesses.

For example, steel is durable and ideal for high-volume production, but it is more difficult to machine. On the other hand, aluminum offers faster machining times and better thermal conductivity, but it wears out more quickly in high-stress environments. Selecting the appropriate material means balancing durability and performance against cost and manufacturing time. Poor material choices can lead to premature wear, mold defects, and ultimately, costly rework.

Machining errors are one of the most common challenges in CNC mold making. Even with high precision, small errors can lead to significant issues. For example, incorrect tool calibration or misalignment can result in molds that don’t fit together properly, affecting the quality of the final product. Issues like surface imperfections, improper tool paths, and inaccuracies in dimensions are common machining errors that can compromise the mold.

To avoid such errors, manufacturers implement quality control measures, including regular inspections and recalibrations. These preventative measures can include using advanced software for tool path simulations and employing skilled technicians who can spot errors early. Additionally, using high-quality tools and materials during the machining process helps minimize the risk of errors and ensures molds meet precise specifications.

One of the biggest challenges in CNC mold making is the high initial cost. CNC machines, tooling, and the setup for the mold-making process can be expensive. The complexity of the mold design and the materials used also contribute to these costs. For example, molds that require complex geometries or intricate features often take longer to machine, increasing production costs.

Despite the upfront expenses, CNC molds are a long-term investment. They provide consistent quality and precision, which are essential for mass production. Once the initial investment is made, the cost per unit decreases significantly, especially for high-volume production. Additionally, CNC molds allow for quick modifications and higher production rates, offering a substantial return on investment over time.

Challenge | Impact | Solution |

Material Selection | Affects mold longevity, quality, and cost | Balance durability, performance, and cost factors |

Machining Errors | Can cause defects and inconsistent mold quality | Regular inspections, tool path simulations, skilled technicians |

High Initial Costs | High upfront costs for machinery, materials, and setup | Long-term investment benefits, faster production cycles |

CNC mold making offers high precision and efficiency, but these benefits come with challenges like material selection, machining errors, and high initial costs. By addressing these challenges, manufacturers can maximize the value of CNC molds and ensure that the molds produced meet the required standards for quality and performance.

CNC molds offer significant benefits, ensuring high precision and efficiency in manufacturing. These molds are essential across industries like automotive, consumer goods, and aerospace. They revolutionize production by enabling faster, more consistent output. Choosing CNC molds allows for cost-effective, high-precision mold making, ensuring better quality and performance. Companies like Huajimould provide value by offering advanced CNC mold solutions, enhancing productivity and reducing costs for their clients.

A: A CNC mold is a mold created using Computer Numerical Control (CNC) technology. It allows for precise, automated shaping of materials, ensuring high accuracy and repeatability in mold production.

A: CNC molds are made by first designing a 3D model, followed by converting it into machine instructions using CAD and CAM software. CNC machines then mill, drill, and shape the mold to the desired specifications.

A: CNC molds offer superior precision, repeatability, and faster production times compared to traditional molds. This makes them ideal for high-volume, cost-effective manufacturing.

A: Common materials for CNC molds include steel, stainless steel, aluminum, and beryllium copper. Each material is chosen based on its durability, thermal conductivity, and the mold’s intended use.

A: The cost of CNC molds varies based on complexity, material, and size. While the initial cost can be high, CNC molds provide long-term savings by reducing errors, rework, and production time.