Views: 0 Author: Site Editor Publish Time: 2026-01-30 Origin: Site

Cooling is often the slowest and most expensive stage in injection molding, because it controls both cycle time and part stability. When heat stays trapped in the core, cooling becomes uneven and creates hot spots, which can lead to warpage, sink marks, and delayed ejection. To solve these issues at the tooling level, many manufacturers adopt conformal cooling, which uses channels that follow the 3D shape of the part instead of straight drilled lines. In this article, you’ll learn what conformal cooling is, how it works inside a mold, and why it helps improve output, quality consistency, and production planning.

Conformal cooling uses cooling channels that follow the 3D shape of the part. Compared to straight drilled cooling lines, it can reach heat-heavy zones more effectively. This is why it often improves both cycle time and part consistency.

Conformal cooling channels are designed to match the contours of the cavity and core. Instead of running straight, they curve around ribs, bosses, corners, and deep pockets. This lets coolant flow closer to the areas where heat builds up, so heat can be removed faster and more evenly.

Channel distance strongly affects heat transfer. When channels sit closer and are spaced more evenly, the plastic reaches a stable solidification state sooner. This matters most in thick sections, corners, and deep ribs, because these zones hold heat longer and often set the cooling time for the entire cycle.

Traditional straight drilled cooling is simple to build, but it cannot reach every hot zone in complex molds. This often creates mold temperature variation and leads to unstable shrinkage. The table below shows the key thermal-control differences.

Aspect | Straight Drilled Cooling | Conformal Cooling |

Channel routing | Limited placement | Follows part geometry |

Hot spot control | Hard to reach hot zones | Targets heat-heavy areas |

Mold temperature | Larger variation | More uniform range |

Part results | Uneven shrink, deformation risk | More consistent shrinkage |

Process stability | More tuning needed | More stable repeat runs |

Most conformal cooling is implemented through mold inserts, not full tool rebuilds. The insert contains conformal channels and fits into a standard mold base. This lowers adoption risk and makes upgrades easier, especially when only one area drives most cycle delay or scrap. Straight drilling often cannot place cooling close enough in complex molds, so conformal cooling inserts become a practical and high-ROI solution.

Applications of conformal cooling include:

● Implementation approach: Mold inserts integrated into standard mold bases

● Heat-heavy core and cavity features:

○Deep rib cores and complex cavities

○ Tall bosses and tight corners

● High-thermal-load process zones:

○Gate regions

○ Thick-to-thin transitions

Below is a short benefit map. It connects thermal control to business outcomes. Each item shows what it changes on the shop floor, not only in theory.

● Shorter cycles: It removes heat faster near hot zones, so we eject earlier without deformation.

● Higher yield: It reduces sinks, warp, and glossy patches linked to uneven cooling.

● More repeatability: It stabilizes mold temperature, so settings drift less over time.

● Lower total cost: It reduces scrap, rework, and the time operators spend tuning.

These benefits also support stronger customer confidence. When parts stay stable, quality claims drop. When delivery stays stable, contracts become easier to renew.

The table below groups common ROI drivers. They belong to the same class: measurable production outcomes. It helps decision makers build an internal case quickly.

ROI Driver | What It Improves | Why It Matters for B2B |

Cycle time reduction | Output per press | Increases capacity without new machines |

Scrap reduction | Yield and cost | Cuts hidden losses and quality disputes |

Dimensional stability | Fit and function | Reduces returns and assembly failures |

Process consistency | Planning reliability | Reduces downtime and schedule risk |

A lot of manufacturers adopt it through staged upgrades. They start with one core insert. They test output and quality data. Then they extend it to other high-heat zones as results prove out.

Heat transfer is highly sensitive to distance. When a channel is close to the mold surface, it can pull heat out faster. But distance alone is not enough. Coverage matters too. If one area has strong cooling and another has weak cooling, thermal gradients still form.

A good conformal layout balances two goals: keep channels close where heat is high, and keep coverage uniform across the cavity. This reduces hot spots and keeps shrinkage balanced.

Channel design must support stable flow. Coolant must move fast enough to remove heat, and the system should avoid dead zones that trap warm fluid. Uniform flow also reduces temperature variation between inlet and outlet.

In practice, designers focus on continuous paths, smooth curves, and controlled pressure drop. The goal is predictable cooling behavior across the tool, not only high flow in one area.

Liquid and gas conformal cooling both aim to improve heat removal, but they fit different production needs. The table below summarizes how each option is typically selected and where it is most often used.

Item | Liquid Conformal Cooling | Gas Conformal Cooling |

Typical coolant | Water-based liquid coolant | Gas coolant |

Heat removal strength | High heat capacity and strong heat transfer | Lower heat transfer compared to liquid |

Best-fit scenarios | Most conformal cooling applications | Space-limited designs or special constraints |

Key advantages | Strongest cycle time benefit in most cases | Helps minimize condensation and corrosion risks |

Selection factors | Part material, mold temperature range, stability needs | Part material, mold temperature range, stability needs |

Instead of only listing features, we can look at how it behaves during a run. Operators see these differences quickly.

● Traditional cooling often needs more tuning as the mold warms up. It also shows defect clusters in fixed zones.

● Conformal cooling often holds settings more steadily. It reduces repeated defect patterns linked to hot spots.

● Traditional cooling may require longer cooling time to protect shape.

● Conformal cooling lets us eject sooner because solidification becomes more even.

Those changes reduce setup time and reduce defect chasing. It also makes it easier to hit promised lead times.

This table compares performance factors that belong together. It avoids mixing unrelated content. It shows what tends to change when conformal cooling replaces straight drilled cooling.

Factor | Traditional Cooling | Conformal Cooling |

Channel geometry | Straight drilled paths | Geometry-following paths |

Hot spot control | Often limited | Stronger local control |

Cooling uniformity | Uneven in complex zones | More balanced across part |

Cycle time potential | Often cooling-limited | Higher speed potential |

Repeatability | More tuning needed | More stable windows |

Not every mold needs conformal cooling. The best ROI comes when cooling is clearly the bottleneck and geometry prevents effective drilling.

Parts with deep ribs, thick bosses, and nested cavities create localized heat buildup. Traditional cooling struggles to reach these areas. Conformal cooling targets these hot zones directly, improving both cycle time and quality stability.

This is often seen in housings, structural components, and functional parts with multiple internal features. If defects repeat in the same area and do not respond well to process changes, conformal cooling can be a better structural fix.

High-volume products magnify small savings. If a tool runs millions of cycles per year, even one second reduction per cycle can produce large capacity gains. Conformal cooling is a strong option when demand is high and machine availability is limited.

In these programs, ROI comes from throughput increase and scrap reduction. It also supports stable production planning, which reduces the cost of late deliveries and emergency overtime.

Best-Fit Scenario | Why It Delivers Big Gains |

Complex geometry hot zones | Targets heat buildup, improves cycle and stability |

High-volume production runs | Small cycle cuts create large capacity gains |

Channels should stay close to the mold surface where heat is highest, while maintaining safe steel thickness. Spacing should be uniform enough to avoid overcooling one region and undercooling another. Distance, spacing, and coverage must work together to create a stable temperature field.

Designers often use repeating channel patterns that cover the cavity evenly. The best pattern depends on part geometry. Curved paths may be used around bosses, while parallel coverage may be used on flat regions. The goal is consistent heat removal across the whole molding area.

Corners and transitions are common warpage drivers. Ribs can hold heat and create sink marks. Thick-to-thin transitions create uneven solidification. Conformal cooling should focus on these zones because they often define both cycle time and scrap rate.

Simulation reduces risk. It predicts hot spots, temperature gradients, and cooling time. It can also estimate cycle time reduction and identify flow weak zones. For many B2B programs, simulation is the step that turns conformal cooling into a reliable investment instead of a trial.

Conformal cooling requires complex internal channel paths, but conventional machining struggles to create them due to access and drilling limits. The table below summarizes the key constraints.

Machining Limitation | What It Means for Cooling Design |

Tool access is restricted | Many internal routes cannot be reached |

Drills move in straight paths only | Curved channel paths cannot be produced |

Multiple drills still have limits | Complex channel networks remain impossible |

Cooling layout must be compromised | Channels stay away from key hot zones |

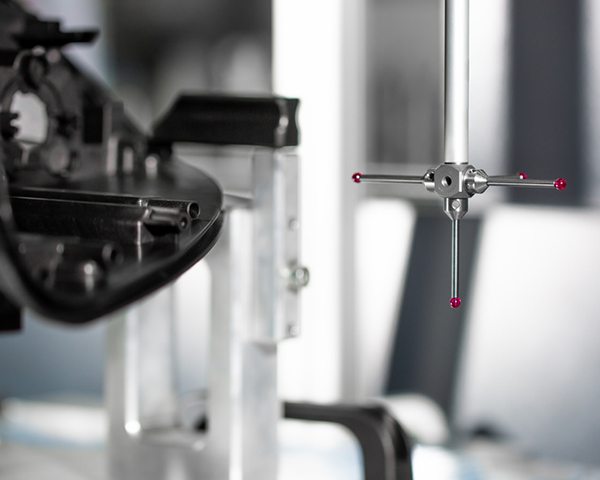

Metal additive manufacturing can create internal channels during the build. This allows curved, branching, and contour-following paths. Inserts printed in metal can then be integrated into standard mold bases, which makes adoption practical for many shops.

Printed inserts require post-processing. Heat treatment improves material properties. Surface finishing improves fit and sealing. Inspection verifies channel integrity and dimensional accuracy. These steps ensure the insert performs reliably under production pressure and temperature.

Insert-based integration is common. It allows teams to upgrade only the cooling-limited area while keeping the rest of the tool unchanged. This reduces redesign scope and helps shorten implementation time.

Tool steels are common for durability. Stainless steels are used when corrosion resistance matters. Aluminum can be used for faster heat transfer in some applications, but it must fit strength needs. Copper alloys can offer high thermal conductivity but require careful design due to wear and strength trade-offs.

In practice, selection depends on production volume, part material, and mold temperature requirements. The goal is reliable performance, not only maximum conductivity.

Water-based coolant is the most common due to strong heat capacity and low cost. Glycol mixes are used when freeze protection is needed. Oil-based fluids can be used for high-temperature applications but have different heat transfer characteristics. Air cooling may appear in niche cases where liquid coolant is difficult.

Most B2B programs focus on stable liquid cooling first, then optimize flow rate, temperature control, and filtration to maintain long-term performance.

Choice Area | Common Options |

Insert materials | Tool steel, stainless steel, aluminum, copper alloy |

Cooling media | Water-based, glycol mix, oil-based, air |

Conformal cooling improves injection molding by controlling heat more evenly. It uses geometry-following channels to remove heat faster than straight drilled cooling, which helps reduce cycle time and improve part consistency. For B2B production, it lowers hot spots and scrap while improving repeatability across long runs. Taizhou Huangyan Huaji Mould Co., Ltd. provides conformal cooling mold inserts and tooling services, helping manufacturers boost throughput and protect quality at scale.

A: Conformal cooling uses channels that follow the 3D part shape, helping remove heat more evenly than straight drilled lines.

A: Conformal cooling improves temperature uniformity, which can shorten cycle time, reduce hot spots, and increase part consistency.

A: By placing cooling closer to heat-heavy areas, conformal cooling pulls heat out faster so parts reach safe ejection sooner.

A: Traditional cooling relies on straight drilled channels, while conformal cooling follows geometry to improve coverage in complex zones.

A: It delivers the biggest gains on complex parts with deep ribs, bosses, or thick sections, especially in high-volume production.

A: It can cost more upfront due to design and manufacturing, but many B2B programs justify it through throughput gains and scrap reduction.