Views: 0 Author: Site Editor Publish Time: 2026-01-21 Origin: Site

Blow molding and rotational molding are two of the most popular plastic manufacturing methods. These techniques are vital in producing everything from everyday items to large, complex industrial parts. But how do you know which one is right for your needs?

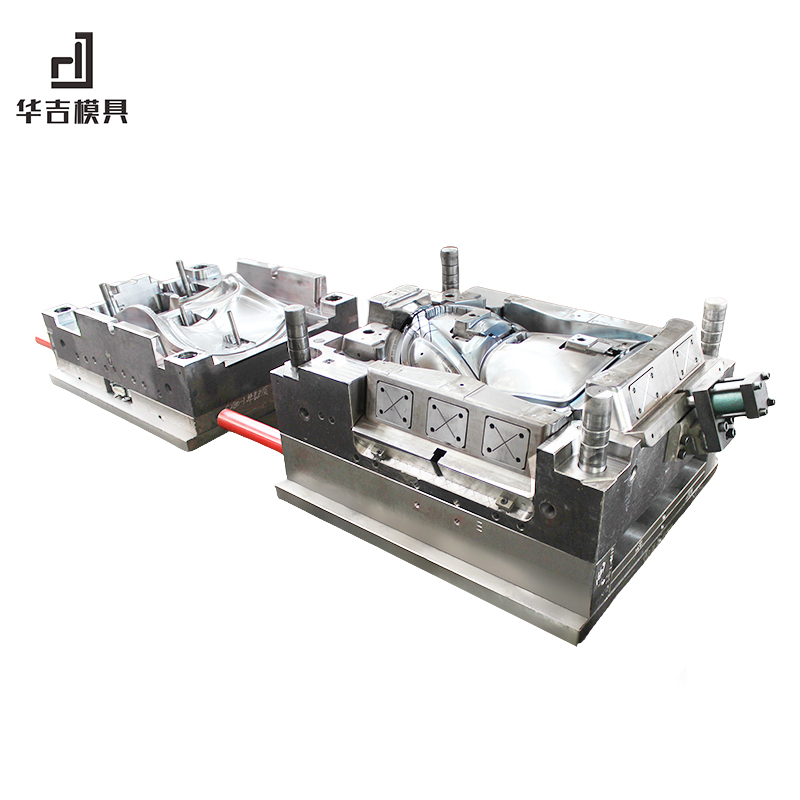

In this article, we will compare blow molding and rotational molding, discussing their processes, advantages, and applications. By the end, you'll be equipped to choose the best method for your production requirements. Huangyan Huaji Mould, a leader in the molding industry, provides high-quality molds for both processes, helping manufacturers achieve faster, more efficient production.

Blow molding is a manufacturing process used to produce hollow plastic parts. It begins with a plastic resin that is melted and extruded into a hollow tube, called a parison. The parison is then heated and placed in a mold. Compressed air is introduced into the parison, causing it to inflate and take the shape of the mold. After cooling, the part is removed from the mold, and it is ready for use.

The process is highly efficient, allowing for the mass production of identical parts in a relatively short period of time. Blow molding is commonly used for producing items such as plastic bottles, automotive fuel tanks, and containers, where lightweight and uniformity are essential.

Blow molding is widely used for products that require hollow forms. Some common applications include:

● Plastic bottles: Often used for beverages, cleaning products, and pharmaceuticals.

● Containers: Such as storage containers for food and other products.

● Automotive parts: Including gas tanks, ducts, and various vehicle components.

● Household goods: Items like lawn mower parts, air ducts, and more.

Huangyan Huaji Mould is well-known for its expertise in designing molds that maximize efficiency in blow molding. Their precision molds help ensure quick turnaround times, making the process ideal for high-volume manufacturing.

Blow molding has several key advantages that make it an excellent choice for high-volume production:

Advantage | What It Means in Production | Why It Matters |

Fast production speed | Short cycle times (often under one minute) allow quick, repeated output of the same part. | Ideal for industries that need large runs, such as beverage packaging. |

Low per-unit cost at scale | Unit cost drops as production quantity increases. | Makes blow molding highly cost-effective for mass production. |

Lightweight, thin-walled parts | Produces light parts with thin walls while keeping shape consistency. | Great for consumer goods where saving material is important. |

Blow molding also allows for greater flexibility in part design compared to other methods, especially in the production of simple, hollow parts.

Rotational molding, or rotomolding, is a manufacturing process that involves heating powdered plastic resin in a mold that is simultaneously rotated on two axes. As the mold rotates, the powder melts and evenly coats the inside of the mold, forming a thick, uniform wall of plastic. The mold is then cooled, and the part is ejected.

This process is particularly well-suited for large parts or parts that need to be thick and durable. Rotational molding is ideal for products that require strength, such as storage tanks or outdoor furniture.

Rotational molding is used to create large, durable products with complex geometries. Some common applications include:

● Storage tanks: Large tanks for water, fuel, and chemicals are commonly produced using rotational molding.

● Playground equipment: Durable, safe products like slides, swings, and climbing structures.

● Kayaks and canoes: The strength and durability of rotational molding make it perfect for watercrafts that need to withstand harsh conditions.

● Industrial containers: Large bins, pallets, and other containers used in warehouses or shipping.

Huangyan Huaji Mould provides molds designed to meet the demanding requirements of rotational molding. Their high-quality molds help manufacturers produce large parts with consistent strength and quality.

Rotational molding offers several advantages, particularly for larger and more complex parts:

Advantage | What It Means in Production | Why It Matters |

Stronger parts | Produces thick-walled parts with high strength and durability. | Great for heavy-use products like industrial tanks and playground equipment. |

Design flexibility | Supports intricate shapes, including multi-layer and double-wall structures. | Helps add insulation, extra strength, or complex geometries. |

Low tooling cost for small production runs | Requires relatively low initial tooling compared to many molding methods. | Ideal for small-volume and custom production runs. |

The process is especially advantageous for low-volume, high-complexity products that demand more from a design perspective, such as large or multi-compartment items.

The primary difference between blow molding and rotational molding is the cycle time. Blow molding is much faster, with cycle times often under one minute. This is especially beneficial for high-volume production, where fast throughput is crucial to meet the demand.

In contrast, rotational molding has a slower cycle time, typically ranging from 20 to 30 minutes per part. While this slow cycle time may seem like a disadvantage, it’s necessary to ensure even heating and consistent wall thickness for larger and more complex parts. For industries producing custom or large parts in lower volumes, rotational molding’s slower pace can be justified by the strength and flexibility it offers.

Blow molding supports a wide range of materials, including polypropylene (PP), polyethylene terephthalate (PET), polyvinyl chloride (PVC), and high-density polyethylene (HDPE). These materials offer various properties such as clarity, flexibility, and durability, allowing manufacturers to select the best fit for their product’s performance.

Rotational molding is more limited in terms of materials. It primarily uses polyethylene (PE) variants, including low-density polyethylene (LDPE), high-density polyethylene (HDPE), and linear low-density polyethylene (LLDPE). While the material options are fewer, PE materials are highly durable, making them perfect for large, robust products like tanks and kayaks.

Item | Blow Molding | Rotational Molding |

Cycle Time | < 1 minute | 20–30 minutes |

Common Materials | PP / PET / PVC / HDPE | LDPE / HDPE / LLDPE |

Best For | High-volume hollow parts | Large, durable complex parts |

Blow molding is much more efficient for high-volume production. With its fast cycle times, blow molding machines can produce up to 70 parts per hour, making it an ideal choice for products with high demand, such as beverage bottles.

Rotational molding, however, is slower, typically producing only two parts per hour. While this slower speed is a disadvantage for mass production, it allows for the creation of parts that are far more complex and durable. As such, rotational molding is better suited for low-volume production runs, especially when the complexity and size of the parts are significant.

While blow molding involves higher initial tooling costs due to the precision required in creating molds, its high production efficiency leads to a lower per-unit cost when producing large quantities. For businesses looking to produce thousands or even millions of parts, blow molding is the most cost-effective choice.

Rotational molding’s tooling costs are lower, making it a more affordable choice for small to medium production runs. However, the slower cycle times and higher material usage result in a higher per-unit cost. This makes rotational molding ideal for lower-volume production of complex, durable parts, where the cost of each unit is less of a concern than the product’s strength and design complexity.

Cost Factor | Blow Molding | Rotational Molding |

Tooling cost | Higher due to precision molds | Lower for many custom shapes |

Per-unit cost | Low at high volume | Higher due to slower cycles |

Best production size | Large batches | Small to medium runs |

Material usage | Often thinner walls | Often thicker walls |

Choosing the right process is not only about speed or cost. It also affects product quality during real production. Sometimes a part looks fine at first, then problems show up later. We often see issues like uneven walls, weak corners, or surface defects. The good news is that most of these problems are predictable, and they can be controlled with the right setup. If you work with a mold supplier like Huangyan Huaji Mould, you can usually reduce defects early and keep output stable.

Blow molding runs fast, so even small changes can affect part quality. If air pressure, resin temperature, or parison thickness shifts, the result may look different right away. When a part feels weak, the parison may have stretched too much. When the shape looks off, cooling or mold alignment could be the cause.

Common issues you may see include:

● Uneven wall thickness: Adjust parison settings and keep air pressure stable.

● Bottom thinning: Reduce parison drop and optimize mold closing timing.

● Air leaks / poor forming: Check sealing, clamping pressure, and air line stability.

Rotational molding is slower, but it still needs stable heating and rotation. If heat is uneven, resin may not bond well in some areas. That can cause weak spots or rough surfaces. If cooling is too fast, parts may warp and lose their shape.

Common issues you may see include:

● Warping / distortion: Balance cooling time and airflow, support the part while cooling.

● Pinholes / bubbles: Dry the powder and keep heating stable.

● Thin corners / weak edges: Improve rotation balance and heating uniformity.

Blow molding is best for simple hollow designs that keep a fairly consistent wall thickness. It performs well for bottles, containers, and similar parts where the shape stays smooth and uniform. However, it becomes harder to manage when designs get more complex, especially if you need thick sections, sharp details, or built-in internal structures. In many cases, it works best when the product design stays clean and straightforward.

Rotational molding offers far more design flexibility. The ability to create parts with multi-layered walls, internal compartments, and intricate designs makes it the preferred choice for custom and complex products, such as kayaks, playground equipment, and large industrial containers.

Blow molding can control wall thickness well for thin-walled parts, which helps reduce material use. But for larger parts, thickness may vary because the parison stretches differently across the mold. That’s why careful setup and process control matter.

Rotational molding is known for thicker and more uniform walls, especially across wide surfaces. This helps parts handle stress better and makes it ideal for tanks, outdoor furniture, and other heavy-use products.

Blow molded parts are usually lighter, which is great when weight matters more than heavy-duty performance. They work well for packaging and everyday consumer items. Rotational molded parts are generally stronger and more durable due to thicker walls and consistent material distribution, making them better for impact, outdoor use, and long-term wear.

Design Factor | Blow Molding | Rotational Molding |

Flexibility | Simple, hollow shapes | Complex, multi-layer designs |

Wall Thickness | Best for thin walls | Uniform, thicker walls |

Strength | Lightweight, lower durability | Stronger, more durable |

Blow molding and rotational molding are essential methods, each offering unique advantages. Blow molding is ideal for high-volume, lightweight parts, while rotational molding suits low-volume, complex, and durable designs. By evaluating production volume, material needs, and part complexity, you can choose the best method for your requirements.

Taizhou Huangyan Huaji Mould Co., Ltd. leads the industry with innovative, high-quality molds for both molding techniques. Their products ensure manufacturers achieve superior results, maximizing both efficiency and product quality.

A: Blow molding inflates a parison to form hollow parts fast, while rotational molding rotates heated resin powder to build thick, durable walls.

A: Choose blow molding for high-volume items like bottles and containers, and choose rotational molding for large, complex parts in lower volumes.

A: Blow molding has higher tooling cost but lower unit cost at scale, while rotational molding has lower tooling cost but higher unit cost per part.

A: Rotational molding requires longer heating and cooling to ensure even coating and wall thickness, while blow molding cycles can be under one minute.

A: Blow molding supports PP, PET, PVC, and HDPE, while rotational molding mainly uses polyethylene variants like LDPE, HDPE, and LLDPE.

A: In blow molding, check parison programming and air pressure; in rotational molding, adjust heating time and rotation speed for more uniform walls.