Views: 0 Author: Site Editor Publish Time: 2026-01-23 Origin: Site

Injection molding is fast and repeatable, yet customers judge quality in seconds. They notice the surface before they notice dimensions or tolerances. That’s why injection molding surface finishes matter beyond looks. They shape grip, clarity, and how paint, coatings, or labels perform in real use.

Because the finish comes from the mold surface, it transfers onto every part you ship. Many manufacturers, including Huaji Mould, treat finish selection as an early quality decision, not a last-minute cosmetic tweak. In this overview, we’ll compare common finish types, explain SPI and VDI references, and show how to choose the right finish for real products.

When people discuss injection molding surface finishes, they’re usually choosing from a small set of finish families. A simple workflow works best: select the finish type that matches the product goal, then apply it only to the surfaces that matter most.

This approach keeps the part visually consistent, reduces unnecessary finishing work, and makes production outcomes easier to control.

High-gloss polished finishes create a mirror-like surface that looks sharp and high-end. They reflect light strongly, so they are often used on customer-facing parts where appearance matters.

This finish family is also common for transparent parts because polishing can improve clarity and reduce haze. You’ll often see it on clear covers, decorative panels, and premium display windows.

Where it fits best

● Clear parts that need strong transparency

● Cosmetic panels designed to look “premium”

● Visible surfaces where reflections look intentional

Semi-gloss finishes sit between mirror polish and matte. They look clean and smooth, but avoid harsh reflections, which helps the part look stable in real lighting.

Many B2B housings and general enclosures use semi-gloss because it delivers a professional look across large surfaces without looking overly shiny.

Where it fits best

● Medical device housings

● Office equipment covers

● Consumer product shells that need a neutral look

Matte finishes reduce glare and soften the visual shape of a part. This often creates a calmer, more modern impression, especially on handheld products.

Matte surfaces can also make daily handling marks less noticeable compared to glossy finishes, which is why they work well for products touched often.

Where it fits best

● Handheld electronics and tools

● Wide cosmetic faces under strong lighting

● Products that need a low-reflection style

Blast and satin finishes create a fine, uniform surface texture that feels technical and controlled. They’re frequently used in industrial products that need a clean appearance without a luxury shine.

They also present consistently across wide surfaces, which makes them easier to approve for equipment covers, enclosures, and functional shells.

Where it fits best

● Industrial enclosures and guards

● Outdoor equipment housings

● Large surfaces needing uniform appearance

Textured injection molding surface finishes are about more than looks—they affect how a product feels in the hand. A light texture can improve grip and comfort, while a stronger texture can communicate brand identity.

Textures are usually applied to touch zones such as grips, sidewalls, and control areas, instead of covering the entire part. That helps the design stay clean and production-friendly.

Where it fits best

● Grip zones and touchpoints

● Wearable-contact surfaces

● Branding areas needing tactile identity

VDI values describe surface roughness in an engineering-focused way. They’re often used in Europe and global projects to align expectations across suppliers.

Instead of naming a decorative pattern, VDI communicates a controlled roughness level that can be matched more consistently during manufacturing.

Where it fits best

● Engineering-driven finish control

● Global supply chains needing alignment

● Technical surfaces needing measurable roughness

Finish family | Visual feel | Typical best-fit parts | Why choose it |

High-gloss polished | Mirror, premium | Clear covers, show faces | Strong clarity and shine |

Semi-gloss | Clean, balanced | Housings, panels | Stable look in real light |

Matte | Soft, modern | Handheld shells | Low glare, hides marks |

Blast & satin | Uniform, technical | Industrial enclosures | Consistent wide surfaces |

Textured finishes | Tactile, branded | Grip zones | Better grip and comfort |

VDI roughness (EDM) | Engineered, controlled | Technical faces | Measurable roughness control |

Surface finish language can get messy fast. Terms like “smooth,” “fine matte,” or “light texture” are subjective, and different teams often imagine different results. Standards reduce that risk by creating shared expectations.

SPI is widely used to describe finish families such as polished, semi-gloss, matte, and blast effects. VDI is often used to express roughness levels and support engineering-driven alignment, especially in international workflows.

SPI grades help teams communicate finish intent quickly. Instead of writing long descriptions, a supplier can understand whether the target is a high polish, a semi-gloss production finish, a matte look, or a blast-style surface.

SPI works especially well when appearance is the main target and you want a consistent “finish family” across parts. It also fits quoting and production discussions because it keeps communication short and repeatable.

The best practice is to apply SPI to specific surfaces rather than the entire part. Cosmetic zoning improves consistency and helps suppliers focus finishing effort where it matters most.

VDI focuses on roughness control, which makes it strong for technical surfaces and global supplier alignment. When multiple vendors are involved, VDI can reduce ambiguity because it expresses the finish intent in a structured way.

VDI is also useful when surface feel and functional texture behavior are key outcomes. It helps projects stay consistent across tools, regions, and production runs, especially when the team wants a measurable “roughness level” rather than a decorative texture name.

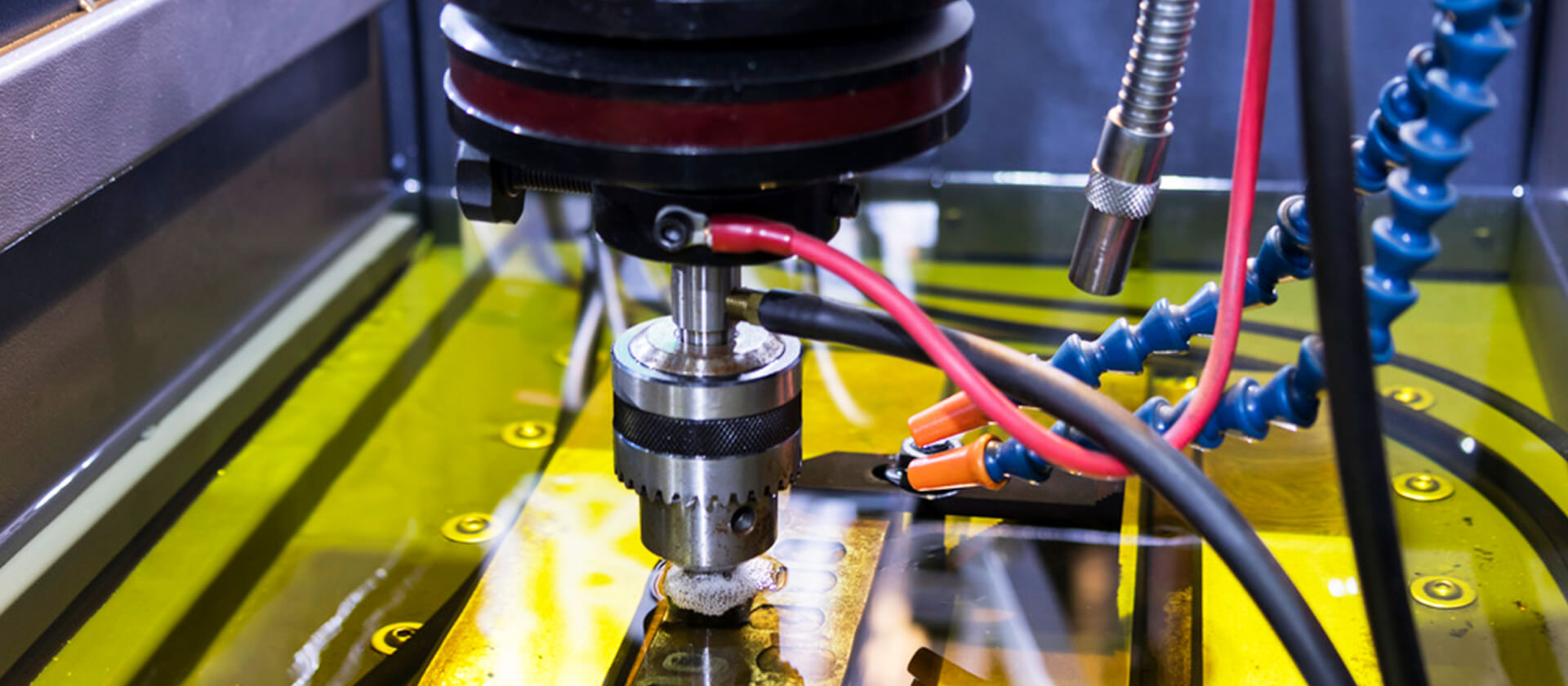

Mechanical polishing removes tool marks and micro-scratches to create smooth or glossy surfaces. The process often uses multiple steps, moving from rougher finishing to fine polishing until the desired gloss level is reached.

High-gloss cosmetic faces usually require careful polishing control, especially on large surfaces. Polishing quality also matters on clear parts, where surface defects can affect clarity. When finish is a key selling point, polishing is one of the most direct ways to raise perceived quality.

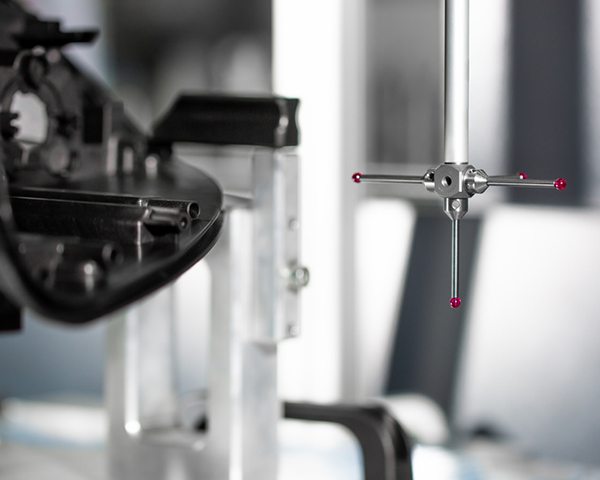

EDM is frequently used to create complex mold features and fine geometry. It can leave a controlled surface texture that supports technical finish goals. For some products, controlled roughness is preferred over high gloss because it creates a stable, industrial look.

EDM-related surfaces can fit programs where the priority is consistent surface behavior rather than premium shine. It’s also helpful when the part needs a technical appearance that remains uniform across viewing angles.

Chemical etching creates texture patterns by selectively removing material from the mold surface. Laser texturing can produce precise, repeatable textures with strong control over detail. Both methods transfer patterns directly to the molded part.

Textures can improve grip, hide minor handling marks, and support branding. When texture is important, apply it to the right zones rather than the whole part. That keeps the design clean and helps the part feel intentional rather than busy.

Method | Result | Best use |

Mechanical polishing | Smooth to high gloss | Clear parts, premium faces |

EDM roughness | Controlled texture | Technical, uniform surfaces |

Etching / laser texturing | Patterned texture | Grip zones, branding feel |

Start with what the surface must do. If the surface needs clarity, a polished finish is usually the best fit. If it needs grip and secure handling, texture often delivers the most value. If low reflection is important, matte or satin finishes reduce glare and keep the surface calm.

For areas that must support labels or coatings, smooth and controlled finishes can help, but outcomes depend on resin and process choices (needs verification). Function-first selection prevents cosmetic choices from creating usability problems later.

After function is clear, we choose the finish by visual feel. Different product styles usually map to different surface directions.

Visual goal | Best finish direction | Typical product type | What it communicates |

Premium highlights | Controlled gloss | Consumer products | Clean, high-end look |

Stable and practical | Soft matte / satin | Professional, industrial | Consistent appearance |

Tactile identity | Textured surface | Touch-focused products | Grip, comfort, branding |

Not every surface deserves the same finishing effort. Separating cosmetic faces from hidden surfaces is one of the easiest ways to control cost and quality at the same time.

A practical approach is to define:

● Primary cosmetic faces users see most

● Secondary visible faces seen occasionally

● Internal faces not judged by customers

Then apply premium finishing only where it will be noticed. This also helps suppliers plan polishing and texturing work efficiently.

Finish decisions should match your stage of development. Early prototypes can validate the “look direction,” while bridge tooling helps confirm how finish transfers on the real production resin.

Production tooling should lock exact surface zones and finish intent. Late changes can be expensive because they require rework on steel. If the finish is a key brand element, validate it earlier with real samples and clear surface zoning.

Material and color can change how the same finish looks and feels, so it’s worth checking the surface “read” early.

Factor | Surface effect | Quick tip |

Hard vs soft resin | Crisp vs softened texture | Test real hand-feel |

Dark vs light color | Strong vs subtle texture | Review under lighting |

Filled resin (needs verification) | More visual variation | Sample on final resin |

Draft improves release and protects cosmetic surfaces during ejection. Textured surfaces typically need more draft than polished surfaces because texture can mechanically grip the mold wall. If draft is too small, texture may appear inconsistent, and release marks can become more likely.

Polished surfaces may allow smaller draft in some cases, but they still need stable release to protect cosmetic quality. A focused DFM review of draft on cosmetic faces often prevents expensive tool rework.

Finish zoning means applying different finishes to different regions of the same part. This is one of the best ways to achieve a premium look without over-finishing everything.

A common strategy is to keep primary show faces semi-gloss or matte, apply texture to grip zones, and leave internal faces as standard production finish. This creates contrast, improves touch experience, and keeps manufacturing practical. Many suppliers—including Huaji Mould—prefer drawings that clearly mark finish zones because it speeds quoting and reduces back-and-forth during tool build.

Electronics housings often use matte or soft textures for a clean, modern feel. These surfaces reduce glare and stay stable under bright lighting. Light texture on touch zones can improve grip while keeping the design calm. A common setup uses matte or semi-gloss on the main show face, then adds subtle texture on side grips for comfort and control.

Clear parts usually rely on high polish to maximize transparency. Polished surfaces reduce haze and create a more glass-like look for windows and covers. This matters most on visible areas, decorative clear shells, and light-related components. If clarity is the key value, polishing the main visible face often delivers the biggest impact without over-finishing hidden faces.

Touchpoints like buttons, grips, and handles benefit from texture because it improves control. Even a light texture can make the product feel safer and more comfortable during use. For professional equipment, touchpoint quality often influences perceived value more than large cosmetic faces. It builds confidence in handling, especially when users wear gloves or move quickly.

Textures can become a signature across a product line. When the feel stays consistent across models, customers recognize it as part of the brand. The cleanest approach is to keep signature textures on specific zones, not the entire part. This creates visual focus, keeps surfaces controlled, and helps the product look intentional instead of overly busy.

Area | Best finish move |

Electronics housings | Matte + light touch texture |

Clear parts & covers | High polish on visible faces |

Functional touchpoints | Texture for control and comfort |

Branding surfaces | Signature texture in key zones |

Good finishes require clear specifications. If a supplier must guess, results will vary. The best callouts are short, structured, and tied to surface zones.

A strong callout includes the finish standard and clearly marked surfaces. Identify the cosmetic zones, then assign each zone the appropriate finish family. This is far more reliable than applying one note to the entire part.

For textures, you can describe the intended look and feel as a texture reference without using serial numbers. The key is clarity: which surfaces get texture, what the texture should achieve (grip, hiding marks, brand feel), and what surfaces remain smooth.

Surface zone | Finish standard | Finish intent |

Primary show face | SPI | Clean appearance, stable under lighting |

Grip zone | Texture reference | Tactile grip, comfortable touch |

Internal faces | Standard production | Non-cosmetic, functional |

Not every face has equal importance. Ranking cosmetic priorities helps suppliers focus finishing effort where it will be judged. Primary cosmetic faces should have the strictest finish control, while secondary faces can be less strict, and internal faces can remain standard.

This approach improves quoting speed and reduces confusion during sample review. Suppliers generally prefer drawings that clearly mark surface zones and cosmetic priority levels, because it makes the project easier to execute consistently.

Injection molding surface finishes shape more than appearance, they impact grip, clarity, and visual stability under real lighting. Good results come from function-first choices, then matching the look to the product goal, while checking resin and color behavior early. Clear finish zones on drawings improve alignment, speed approvals, and keep cosmetic quality stable from first samples to mass production. Taizhou Huangyan Huaji Mould Co., Ltd. supports reliable tooling and finish control, helping customers shorten iterations and deliver consistent parts at scale.

A: Injection molding surface finishes are the polish or texture formed on the mold and transferred to the part.

A: Injection molding surface finishes affect grip, clarity, fingerprint visibility, and how stable a part looks under real lighting.

A: Choose injection molding surface finishes by function first, then align the look to your brand, and apply them only to key surface zones.

A: SPI groups finishes by visual families like gloss or matte, while VDI focuses on measurable roughness levels.

A: Injection molding surface finishes for clear parts often use high-gloss polishing to improve transparency and reduce haze.

A: Yes, injection molding surface finishes such as light textures can improve grip on touch zones like handles or sidewalls.