Views: 0 Author: Site Editor Publish Time: 2025-12-10 Origin: Site

Manufacturing today demands more speed and accuracy than ever. Small errors can slow production and raise costs. CNC machining changes this by delivering precise, repeatable results from prototype to mass production. It also strengthens CNC mold manufacturing, reducing bottlenecks and improving part quality. In this post, you’ll learn how CNC machining can upgrade your entire production process.

CNC machines hold tight tolerances, while manual tools shift easily and create variation. This accuracy lowers rework, and it keeps multi-step workflows stable because small errors do not stack across setups. It also helps CNC molds stay consistent, so every molded part follows the same dimensions even in long production runs.

CNC systems run nonstop, and they maintain output during nights or weekends. They never slow from fatigue, and they keep production steady through long cycles. Multi-axis machining cuts several features in one pass, and toolpath automation removes delays caused by manual decisions, giving teams smoother timelines and faster delivery.

One machine handles early prototypes, then moves directly into mass production. Designers adjust CAD or CAM files, and the machine reads updates instantly, speeding every iteration. It also removes the need to build new tools for concept testing, since the digital program controls the entire shape from start to finish.

CNC programs shape material precisely, and optimized toolpaths use every inch of a sheet or block. Nesting places each part tightly, so scrap drops sharply for metals and composites. It also lowers material costs for expensive alloys such as titanium or aluminum, because it avoids waste from human error or inaccurate cuts.

CNC machining achieves shapes manual tools cannot reach. Deep cavities, curved surfaces, and organic forms appear cleanly when the machine moves across many axes. These abilities matter in aerospace, automotive, and medical work, where complex geometry supports performance and safety.

Operators stand farther from cutting tools, and contact drops sharply, reducing accidents. Machines handle heat, chips, and motion, and this creates safer environments for CNC mold work. Cleaner processes also reduce stress on workers and keep attention focused on inspection or programming.

CNC machining supports low-volume flexibility, then shifts into stable high-volume output using the same digital file. Digital replication keeps each cycle accurate, and it maintains part quality even as production grows.

Benefit Area | What It Improves | Practical Impact |

Precision | Dimensional stability | Fewer defects and less rework |

Automation | Labour efficiency | Faster cycles, steady output |

Prototyping | Design speed | Quick testing and updates |

Material Use | Waste reduction | Lower material spending |

Geometry | Complex shaping | Better part performance |

Safety | Lower risk | Safer workstations |

Scaling | Cost control | More output, same resources |

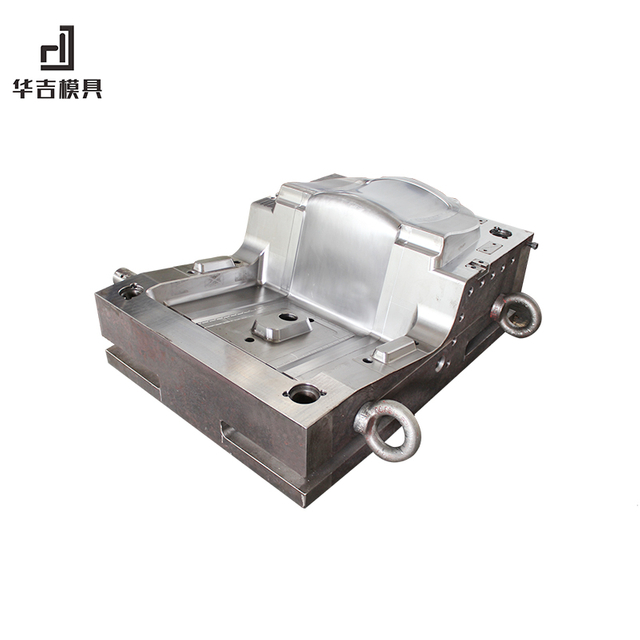

CNC machining creates mold cavities that stay accurate during long production runs, and it keeps part dimensions stable for high-volume injection molding. Tight tolerances protect each cavity from early wear, and they help the mold run smoothly under continuous pressure. It also maintains uniformity across thousands of molded parts, reducing scrap and cutting the risk of size variation.

CNC machines finish mold inserts faster than manual milling or EDM, and they shorten the entire tooling cycle. It reduces setup tasks, and it combines multiple machining steps into a single program, which speeds every stage. Shops use one fixture for many features, so overall lead times drop, and projects move quickly from tooling to first production shots.

CNC machining handles designs that require multi-slide structures, deep undercuts, or conformal shapes. It processes these forms cleanly, and it gives mold designers more freedom, because the machine reaches angles and surfaces unused by traditional tools. It also supports advanced mold structures without forcing teams to change key design details, which helps preserve part performance.

CNC machining lowers structural risk inside the mold, and it avoids errors that appear in manual cutting. Accurate toolpaths protect critical areas from uneven cuts, and they improve mold strength over time. It also creates a better surface finish, reducing the polishing work needed before the mold enters production. A smoother surface improves flow during injection, and it helps the mold last longer.

Mold-Making Method | Key Strengths | Limitations |

CNC Machining | High accuracy, fast lead times, complex geometry | Limited for extremely deep cavities |

EDM | Excellent for sharp corners, fine details | Slower cycle, higher cost |

Manual Milling | Low initial cost | Poor precision, high labor demand |

● Tight tolerances for long-running molds

● Faster mold insert production

● Clean transitions on angled surfaces

● Stable structural performance

● Reduced polishing and finishing time

Manual machining often slows production, and it forces teams to repeat setups many times. Each new setup adds risk, and small errors stack across multiple operations, which creates tolerance issues that harm part quality. CNC machining removes these problems, because it completes many features in one secure setup, and it keeps dimensions stable while cutting. It also reduces interruptions, since the machine follows a programmed path and maintains accuracy through long cycles. This stability lowers scrap, and it protects tight schedules from delays caused by human error or tool changes.

CNC machining works well for parts at both size extremes, and it adapts quickly to different requirements. Micro-machining tools cut extremely small features, and they hold precise dimensions on tiny components used in electronics or medical devices. For oversized parts, CNC machines support rigid frames and strong motors, so large components stay stable without complex fixturing. It shortens setup work, and it reduces the chance of vibration or movement during cutting, which helps maintain clean surfaces and accurate edges. These abilities make CNC machines useful for industries that handle demanding shapes and varied part sizes.

Production lines must deliver thousands of parts that match perfectly, and CNC automation keeps quality stable over long runs. The machine never tires, and it avoids the inconsistency seen in manual processes, where fatigue or distraction creates variation. Automation also ensures steady tool motion, and it repeats the same commands for every cycle, which improves reliability. High-speed machining reduces lead times, and it cuts repeated tasks that slow teams down. It also prevents quality drift, because CNC equipment maintains a controlled environment and recalibrates when needed.

Production Challenge | Traditional Result | CNC Machining Solution |

Multiple setups | Higher error risk | Single-setup stability |

Tiny features | Poor repeatability | Precision micro-machining |

Oversized parts | Difficult fixturing | Strong support structures |

High-volume runs | Quality drift | Automated consistency |

Human fatigue | Variable outcomes | Reliable zero-fatigue workflow |

The automotive sector depends on strict tolerances, and it requires durable parts that hold accuracy during long vehicle lifecycles. CNC machining supports these needs, and it produces engine blocks, transmission housings, and suspension parts quickly. It also handles complex contours, as multi-axis machines cut several faces in one setup, which shortens cycles and raises throughput. The process removes variation created by manual methods, and it keeps every batch consistent, which helps automakers meet rising production demands.

Aerospace manufacturers rely on lightweight metals, and they require smooth surfaces that withstand extreme forces. CNC machining cuts titanium, aluminum, or Inconel cleanly, and it preserves strength by holding tight tolerances across thin-walled structures. Multi-axis motion reaches complex aerodynamic angles, and it forms deep cavities used in turbine blades or airframe parts. These shapes demand accuracy, and CNC machines maintain it even during long runs. The process also lowers waste, which matters for expensive aerospace materials.

Electronics rely on tiny components, and they must fit together without gaps or distortion. CNC micro-machining cuts small housings, buttons, frames, and connector bases while keeping dimensions accurate to fractions of a millimeter. It also supports high-volume runs, and it prevents error drift caused by high operator fatigue in manual work. Clean edges help ensure device durability, and the fast cycle times keep product launches on schedule in a competitive technology market.

Medical manufacturing demands perfect accuracy, and it requires materials that remain stable during sterilization or long-term use. CNC machining handles surgical tools, implant components, and diagnostic device parts that must follow strict regulations. It shapes stainless steel, titanium, and specialized polymers cleanly, and it protects critical areas from burrs or deformation. Machines repeat the same path for every cycle, and they support documentation needed for regulatory audits. Smooth surfaces also reduce contamination risk, and they improve patient safety.

Industry | Key Needs | CNC Machining Capabilities |

Automotive | High volume, fast cycles | Multi-axis machining, stable tolerances |

Aerospace | Lightweight materials, complex shapes | Tight tolerances, low waste |

Electronics | Miniaturization, precision | Micro-machining and consistent accuracy |

Medical | Safety, regulatory compliance | Clean cuts, repeatability, quality control |

A strong CNC partner relies on advanced machines, and it uses tooling that supports accuracy during long production cycles. Multi-axis machines help reduce setups, while high-speed spindles improve surface finish and shorten machining time. It also matters that the partner handles a wide range of materials, because different metals or polymers require specific speeds and tool coatings. Shops using modern CAD/CAM systems adapt faster to design changes, and they deliver cleaner toolpaths for complex shapes.

Clear questions help companies understand whether a CNC partner fits their needs. Teams should ask how the shop maintains accuracy during long runs, and they should check how often machines undergo calibration. Another key question explores how the partner manages quality inspections, since consistent results depend on reliable measurement tools. It is also important to ask how they handle rush orders, because flexible scheduling supports industries facing tight deadlines. These questions reveal strengths in workflow and communication, which influence overall success.

Lead time determines how fast a project can move from design to production, and it affects the entire supply chain. A good partner gives realistic timelines, and it provides clear updates when workloads shift. Material capability also matters, because parts made from aluminum, stainless steel, or titanium require different cutting strategies. Tolerance control is another critical factor, and it guides decisions for industries where small deviations cause failure. Shops that document their tolerances and track them through digital systems offer more dependable results.

Outsourcing gives companies access to advanced equipment without paying for expensive machines or maintenance. It allows teams to focus on design and assembly, while skilled machinists handle complex cutting tasks. Outside shops often run multiple machines at once, and they adapt quickly to changing volumes or part revisions. Their experience helps reduce error rates, and it cuts the cost of hiring or training specialized staff. Outsourcing also supports small businesses, since they gain the precision and repeatability needed for high-quality production without investing in heavy infrastructure.

Evaluation Area | What to Look For | Why It Matters |

Machine Types | Multi-axis, high-speed spindles | Faster cycles and cleaner surfaces |

Material Skills | Metals, plastics, composites | Wider production flexibility |

Tolerance Control | Documented accuracy levels | Higher part reliability |

Lead Times | Fast, predictable schedules | Stronger supply chain |

Quality Systems | Calibration, inspection tools | Consistent long-run output |

Communication | Clear updates and support | Smoother project management |

IoT-connected CNC machines give factories real-time visibility, and they help operators track vibration, heat, and tool wear as the machine runs. Sensors gather data constantly, and it alerts the team before a spindle or bearing reaches a failure point. This predictive approach prevents sudden downtime, and it keeps production schedules stable, since repairs happen at planned intervals instead of emergency stops. The system also stores performance data, and it helps engineers adjust toolpaths or cutting speeds to extend tool life and improve part accuracy.

Digital twins let teams test machining strategies in a virtual environment, and they reduce the risk of mistakes during real production. The model copies the machine, the part, and the cutting tools, so engineers can preview how each move affects the final result. It also shortens setup time, because the program adjusts toolpaths before the machine touches the material. These simulations help detect collisions, and they find inefficient motions that slow the cycle. Digital twins make it easier to transition from prototype to full-scale production, and they support continuous improvement through faster iteration.

Robotics adds more automation to CNC workflows, and it helps factories move toward lights-out manufacturing. Robots load raw stock, and they unload finished parts without stopping the spindle. This integration keeps the machine running longer, and it reduces idle time created by manual handling. Robots also handle repetitive tasks safely, and they reduce the physical strain on workers. When robots and CNC machines work together, they form a fully automated cell that produces parts consistently, even across long shifts or overnight cycles. It increases flexibility, because a single robotic arm can serve multiple machines, which boosts efficiency across the entire shop.

Tip: A small improvement in sensor calibration or robot timing can raise CNC machine uptime dramatically, and it often saves more time than upgrading hardware.

CNC machining improves precision, speed, and quality, and it supports scalable production for parts and CNC molds. It also strengthens workflows and reduces delays, making it a smart long-term strategy for any team. Huajimould offers reliable solutions and durable products that help businesses achieve these benefits and keep production running efficiently.

A: CNC machining increases accuracy, and it helps a CNC Mold produce consistent parts with fewer errors.

A: It holds tight tolerances, so a CNC Mold stays stable during long runs and avoids repeated corrections.

A: Yes, it reduces labour, cuts scrap, and keeps CNC Mold tooling efficient for high-volume work.

A: It uses one setup for both stages, and it allows fast updates without rebuilding the CNC Mold.

A: It handles advanced geometries easily, and it ensures a CNC Mold can support detailed shapes.