Views: 0 Author: Site Editor Publish Time: 2025-12-08 Origin: Site

Choosing the right manufacturing process can make or break your project. CNC Machining and Injection Molding are two popular methods, each with its strengths and weaknesses. The decision impacts not just cost but also the quality and efficiency of your production. In this post, we'll explore the key differences between these methods and help you determine which one suits your needs best.

CNC (Computer Numerical Control) Machining is a manufacturing process where computer-controlled machines remove material from a workpiece to shape it into a desired form. It is often used for producing highly precise parts and components. In CNC machining, the computer controls various tools that cut, drill, and shape materials with extreme accuracy.

The key components involved in CNC machining include:

● Cutting Tools: These are used to remove material and shape the workpiece. Common tools include drills, end mills, and lathes.

● Workpieces: The raw material that will be shaped. These can range from metals like aluminum and steel to plastics and composites.

● Control Systems: The computer software that dictates the machine's actions based on the design specifications, typically through G-code.

CNC machining is suitable for a wide range of materials, including metals (steel, aluminum, titanium), plastics (PVC, polyethylene, acrylic), and composites. This flexibility makes it ideal for creating custom parts with tight tolerances and complex geometries.

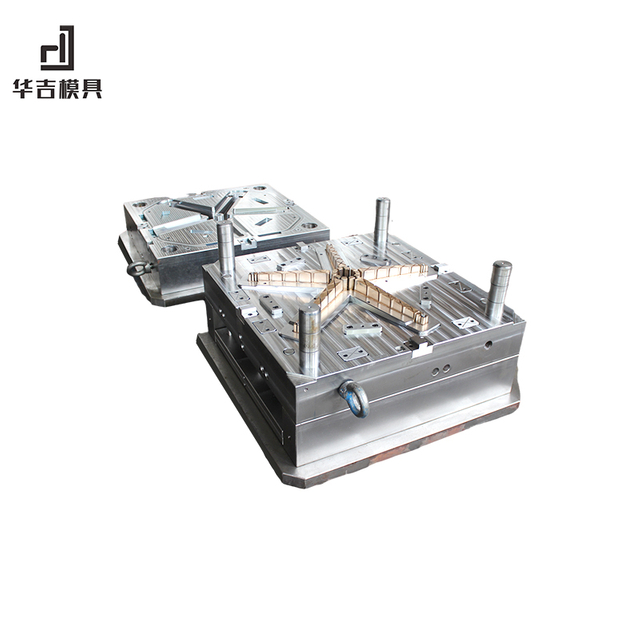

Injection molding is a manufacturing process used to produce parts by injecting molten material into a pre-designed mold. It is commonly used for high-volume production of plastic parts with complex shapes and detailed features.

Key components involved in injection molding include:

● Mold: A custom-designed cavity that shapes the part during the injection process. The mold is typically made from steel or aluminum and is the most expensive part of the setup.

● Injection Unit: This unit melts the material and injects it into the mold under high pressure. It controls the temperature and pressure of the injected material.

● Clamping Unit: This holds the mold closed during the injection process and ensures the mold doesn’t open prematurely.

Injection molding is primarily used with plastics and thermoplastics such as polypropylene (PP), acrylonitrile butadiene styrene (ABS), and polyethylene (PE). It’s ideal for creating high-quantity, consistent parts quickly, though it requires significant upfront investment for mold creation.

Feature | CNC Machining | Injection Molding |

Material Types | Metals, plastics, composites | Plastics, thermoplastics |

Process Type | Subtractive (removes material) | Additive (injects molten material) |

Ideal Volume | Low to medium volume | High-volume production |

Precision | High precision (±0.005 inches) | Moderate precision (±0.020 inches) |

Lead Time | Short (weeks) | Longer (weeks for mold creation) |

These differences highlight the importance of selecting the right method based on your project's needs, whether it’s a prototype, small batch, or large-scale production.

CNC machining uses a subtractive process, meaning it removes material from a solid block to create the final shape. The machine follows programmed paths, and it cuts layer by layer until the design is achieved. It relies on sharp tools, stable fixtures, and accurate computer control, so the results stay highly consistent. The entire process gives engineers more freedom when they need smooth finishes or sharp internal corners.

Injection molding works very differently, because it forms parts by injecting molten material into a mold cavity. The mold defines every feature of the final part, and the molten plastic fills even tiny details. After the material cools, the mold opens, and the part is ejected. The cycle repeats quickly. This method enables rapid production once the mold is built, but it demands a high upfront investment.

CNC machining supports a wide range of materials, such as metals, engineering plastics, and even composite blocks. It can cut aluminum, steel, brass, or tougher materials. It can also shape harder plastics where precision matters, so it’s often used for functional prototypes. These materials stay stable during cutting, and they handle tight tolerances well.

Injection molding relies mainly on plastics and thermoplastics, because these materials melt and flow easily. Common options include ABS, PP, PE, and nylon. They work well when strength, flexibility, or impact resistance is required. Manufacturers often add fillers or colorants to improve performance. Since these plastics melt smoothly and cool quickly, the process supports high-volume production of durable parts.

CNC machining fits low to medium production volumes. It is flexible, because you only need a digital file and raw material. When changes happen, the engineer updates the program, and the next part reflects the new design. This makes CNC machining ideal for prototypes, custom items, or small batches where accuracy matters and speed is secondary.

Injection molding performs best in high-volume environments. Once the mold is created, each cycle takes seconds or minutes, so production ramps up fast. The cost per part drops dramatically as quantity increases. Companies choose injection molding when they need consistent parts for long-term products, large orders, or consumer goods that require repeatability.

Feature | CNC Machining | Injection Molding |

Process Type | Subtractive cutting, tool-driven | Molten plastic injection into mold |

Material Range | Metals, hard plastics, composites | Thermoplastics, elastomers |

Best For | Custom parts, prototypes, small batches | Mass production, high volume |

Design Freedom | High flexibility, easy changes | Limited once mold is built |

Upfront Cost | Low | High due to mold creation |

CNC machining offers strong flexibility for custom or complex designs because it does not rely on fixed molds. Engineers can create sharp edges, deep pockets, or undercuts more easily, as the tools follow programmed paths rather than mold geometry. It works well when the design is still evolving, since updates to the CAD file can be made quickly and the machine reflects those changes immediately. This allows teams to build prototypes, test them, and adjust the design without the cost or delay of rebuilding a mold. It also supports one-off parts or small batches where customization matters more than high-volume speed.

CNC machining delivers tight tolerances, often close to ±0.005 inches, due to direct control over cutting paths and stable machine movements. This level of accuracy is valuable for industries such as aerospace, medical devices, or robotics, where parts must fit together perfectly. It creates clean edges, smooth surfaces, and detailed contours without marks left by ejector pins or flow lines. The cutting tools remove material cleanly, so many parts require little to no polishing. When the product demands consistency or long-term mechanical stability, the machining process supports those requirements effectively.

CNC machining handles a wide range of materials, giving engineers the freedom to choose metals, engineering plastics, or composites based on performance needs. Metals like aluminum, steel, and brass machine well and provide strong mechanical properties for load-bearing parts. Hard plastics such as ABS, PEEK, or nylon also cut cleanly, allowing teams to build functional prototypes that mimic real-world performance. Because the machine does not melt the material, sensitive or heat-resistant materials retain their strength during production. This makes CNC machining a useful option for parts that must withstand stress, heat, or chemical exposure.

Feature | CNC Machining | Injection Molding |

Design Changes | Easy digital updates | Requires new mold |

Precision Level | Very high, tool-controlled | Moderate, mold-dependent |

Material Range | Metals, hard plastics, composites | Mostly thermoplastics |

Best For | Custom designs, prototypes | High-volume plastic parts |

CNC machining fits projects that need flexibility, because it can produce single parts or small batches without requiring molds. The machine reads a digital file, and it cuts the shape directly from solid material, so design changes happen quickly and cheaply. This makes it a strong choice for prototypes, intricate designs, or parts that require very tight tolerances. Engineers can test a design, adjust it, and run new samples in a short time.

Industries such as aerospace, medical devices, and automotive rely on CNC machining when accuracy or durability matters. It works well for brackets, housings, implants, or functional components that demand high performance. Many companies also use CNC machining to validate geometry before investing in a full mold, reducing risks during early development.

Injection molding becomes the preferred method when production reaches high volumes. Once the mold is created, the process runs in fast cycles, and each part forms inside a controlled cavity. The result is a consistent shape, smooth surface, and stable performance across thousands of units. It is suited for producing plastic parts where uniformity and speed are essential.

Industries producing consumer goods, automotive interiors, or electronic housings depend on injection molding because it keeps costs low when the quantity is high. The method supports detailed textures, thin walls, and repeatable dimensions, allowing manufacturers to meet long-term demand. By using automation, the process stays efficient and steady, even for very large orders.

Feature | CNC Machining | Injection Molding |

Best Use Case | Prototypes, custom parts | Mass production |

Production Volume | Low to medium | High |

Design Flexibility | Very flexible | Fixed after mold creation |

Common Industries | Aerospace, medical, automotive | Consumer goods, electronics, automotive |

Change Speed | Fast digital updates | Slow, new mold required |

CNC machining uses a subtractive method, so it removes material from a solid block to form the final shape. This process generates chips, shavings, and leftover sections that often cannot be reused directly. Some materials can be recycled, yet the overall waste remains higher than in additive or molding-based systems. Projects that rely on metals or high-strength plastics often see significant material loss during production.

Injection molding, on the other hand, produces less waste because molten plastic fills the mold cavity precisely. Any excess material from sprues or runners can be collected, reprocessed, and reused in later cycles. The process keeps waste low, and it supports more efficient use of raw materials. This efficiency becomes important for companies focused on sustainability, especially when production volumes rise and consistency matters.

CNC machining typically requires more energy per unit produced, because the machine runs for long periods while cutting material. It holds the workpiece, moves the tools continuously, and maintains stability throughout the process. Energy use increases when the design is complex or when the material is dense. The longer cycle time contributes to higher overall consumption, which makes the environmental impact more noticeable in large batches.

Injection molding machines consume energy as well, but the process becomes more efficient during high-volume runs. Heating the plastic and injecting it into molds uses power, yet each cycle produces a new part quickly. The short cycles help reduce energy consumption per part, especially when the mold supports repeatable production. Manufacturers evaluating sustainability often look at long-term energy efficiency, because material flow, cycle time, and output speed influence the total environmental footprint.

Environmental Factor | CNC Machining | Injection Molding |

Waste Level | High, subtractive removal | Low, recyclable excess |

Energy Use per Part | Higher, long cycle time | Lower at scale |

Material Efficiency | Moderate | High |

Best Fit for Sustainability | Small batches, precision parts | Large-scale, low-waste production |

Tip: When sustainability matters, consider total lifecycle impact—material type, production volume, and waste recovery all influence the greener choice.

CNC machining and injection molding differ in speed, cost, materials, and precision. Each method fits different volumes, design needs, and sustainability goals. Choosing the right process depends on how many parts you need and how complex the design is. Huajimould supports both options and offers high-quality solutions that help teams boost efficiency and product performance.

A: CNC machining cuts material directly, while injection molding uses a CNC mold to form molten plastic into shape.

A: CNC machining works better for small batches or prototypes, while a CNC mold suits large runs.

A: A CNC mold lowers the per-unit cost once mass production begins.

A: Yes, CNC machining offers higher precision, while a CNC mold focuses on speed and consistency.