Views: 0 Author: Site Editor Publish Time: 2025-12-05 Origin: Site

CNC technology has revolutionized modern manufacturing, especially in the moldmaking industry. But how exactly does CNC fit into the moldmaking process? What are the key advantages it brings to this craft? In this article, we'll explore the role of CNC in moldmaking, its benefits, and how it enhances precision and efficiency in the production of molds.

CNC technology is known for its ability to produce extremely precise and consistent results, which is crucial in moldmaking. When creating mold cavities, CNC machines can achieve micron-level accuracy, ensuring that every detail of the mold matches the design specifications. This precision extends beyond the cavity itself to other critical features of the mold, such as venting channels and cooling systems, which are essential for the mold’s performance. CNC machinery eliminates the variances introduced by manual processes, ensuring that each mold produced meets strict quality standards, leading to reliable, repeatable results over time.

Traditional moldmaking relies heavily on manual craftsmanship, where artisans use hand tools to shape and refine the molds. While this approach offers flexibility and customization, it also introduces a significant degree of human error and can be time-consuming. In contrast, CNC machines are driven by computer programs that follow precise instructions from CAD models, significantly reducing the risk of errors and improving production speed.

Unlike traditional methods, which may require several iterations and manual adjustments, CNC machining allows for the creation of complex mold features in a single setup. With multi-axis CNC machines, manufacturers can design intricate, three-dimensional shapes that would be nearly impossible to achieve with traditional handcrafting techniques. However, the transition to CNC moldmaking also presents challenges, such as the need for skilled operators and the initial investment in CNC technology.

Feature | Traditional Moldmaking | CNC Moldmaking |

Precision | Relies on manual skill | High precision, micron-level accuracy |

Time Efficiency | Time-consuming, manual adjustments | Faster production, consistent results |

Complexity | Limited by manual techniques | Can produce intricate, complex shapes |

Customization | Highly flexible | Customization through programming, but with initial setup cost |

Error Rate | Higher due to human factors | Lower, minimal human error |

In high-volume production, CNC machines shine by increasing speed and efficiency. Once a mold design is finalized and programmed, CNC machines can run continuously with minimal supervision, producing identical parts with exact consistency. This capability is especially useful in industries where large quantities of molded parts are required, such as automotive and consumer goods.

CNC machining reduces the reliance on skilled labor, which is often needed in traditional moldmaking methods. By automating many of the manual processes, CNC machines streamline production and significantly cut down on lead times. In addition, CNC machines can handle tough materials and intricate designs without compromising on quality, further boosting their utility in high-volume settings. The ability to repeat the same design accurately and consistently is a key advantage when producing molds for mass production, leading to lower costs and higher output efficiency.

CNC's contribution to high-volume production not only speeds up the process but also minimizes human error. By automating the process, it ensures that each mold and part meets the desired specifications without requiring constant oversight, making it a powerful tool for modern manufacturing.

CNC milling plays a critical role in moldmaking, especially for creating intricate mold cavities. This process uses rotary cutters to remove material from a workpiece, allowing for the precision necessary to carve complex shapes. CNC mills are capable of achieving extremely tight tolerances, ensuring that the mold cavity matches the exact specifications of the part being produced. This capability is vital for molds used in industries such as automotive or medical device manufacturing, where part precision is crucial. The versatility of CNC milling machines, such as their ability to work on multiple axes, makes them ideal for crafting detailed cavities that would be difficult, if not impossible, to create by hand.

CNC turning is essential for creating round mold cores, a key component in many molding processes. In CNC turning, a workpiece is rotated against a stationary cutting tool, removing material to create cylindrical shapes. This process is particularly useful for molds that require round, uniform cores, such as those used in injection molding or casting. CNC turning machines allow for high-speed production while maintaining tight tolerances, ensuring consistency across large production runs. The precise control provided by CNC turning ensures that mold cores have the correct dimensions, which is essential for the uniformity and performance of the molded parts.

Wire EDM (Electrical Discharge Machining) is an advanced technology used for creating fine details and intricate features in mold design. In this process, a thin wire is used as an electrode to erode material from the mold surface, allowing for extremely detailed work. This is particularly useful when dealing with hard materials that are difficult to machine using traditional methods. Wire EDM can create complex, high-precision features such as small cavities, fine vents, and intricate cooling channels. Its ability to create sharp corners and tight radii makes it an indispensable tool for creating molds with highly detailed geometries. The level of accuracy and detail achievable through Wire EDM ensures that molds are functional and meet the specific requirements of the final product.

Ball end mills are a key tool in CNC machining, especially for creating smooth, contoured surfaces in molds. These tools feature a rounded edge that allows them to produce intricate, curved surfaces with high precision. When used in moldmaking, ball end mills are ideal for machining areas with complex, 3D geometries, ensuring smooth transitions between surfaces. The ability to achieve smooth contours is vital for proper material flow during molding, as it reduces areas where material can get trapped, preventing defects. Additionally, ball end mills help in achieving the desired surface finish, which can reduce the amount of hand-finishing required, speeding up the overall production process.

Technology | Key Use | Advantages | Applications |

CNC Milling | Creating intricate cavities | High precision, tight tolerances | Automotive, medical devices, aerospace |

CNC Turning | Creating round mold cores | Fast production, uniform shapes | Injection molding, casting |

Wire EDM | Fine details and intricate features | Precision in hard materials, fine details | Complex mold features, cooling channels |

Ball End Mills | Creating smooth, contoured surfaces | Smooth surface, reduces material traps | Injection molding, die casting |

These CNC technologies combine to form a complete solution for producing highly detailed, accurate molds. Each technique brings its strengths to different aspects of moldmaking, ensuring that every part of the mold is optimized for performance and quality.

Surface finish plays a crucial role in the functionality of molded parts. A mold's surface quality directly affects how the molded material fills the cavity, adheres to the mold, and releases once the part has solidified. A rough surface can cause material to stick, leading to difficulty in part release, while an overly smooth finish may result in poor material flow, causing incomplete filling or defects in the final part. Additionally, certain industries, such as medical devices or automotive components, require highly precise surface finishes to meet both functional and aesthetic standards. CNC machining allows for precise control over these finishes, ensuring the mold performs as intended and minimizes post-production issues.

CNC technology has advanced to the point where it can significantly reduce the need for post-CNC hand finishing. Traditionally, after the CNC machining process, molds would often require manual polishing and finishing to achieve the desired surface quality. However, with the use of specialized tools like bull-nosed end mills, CNC machines can achieve smoother and more precise finishes directly on the mold surface. These tools have a rounded edge that helps create contoured surfaces, reducing the need for further hand-finishing steps. By achieving a smoother surface directly from the CNC machine, manufacturers can save time and labor costs, making the moldmaking process more efficient while ensuring a higher level of accuracy and consistency in surface finishes.

Achieving uniform surface finishes across a batch of molds is essential for maintaining the quality and performance of molded parts. CNC technology excels in producing consistent finishes due to its high precision and repeatability. Unlike traditional manual methods, CNC machines can replicate the same finish for each mold in a production run, ensuring that every part meets the same specifications. The integration of advanced CNC tools and technology enables manufacturers to optimize surface textures, whether they need a glossy, matte, or textured finish. With CNC's ability to control tool movement on multiple axes, manufacturers can achieve intricate patterns and textures with a high degree of consistency, improving both the visual appeal and the functional performance of the final product.

Technology | Surface Finish Type | Key Benefits | Applications |

CNC Milling | Smooth, textured, or matte | High precision, reduced hand-finishing | Automotive, consumer goods, medical |

Bull-Nosed End Mills | Contoured, smooth | Reduces hand-finishing, precision | Complex mold shapes, detailed cavities |

CNC Turning | Smooth, round surfaces | Uniformity in round mold cores | Injection molds, casting molds |

Wire EDM | Fine, detailed surfaces | Precise, intricate features | High-detail mold designs, cooling channels |

Through CNC machining, manufacturers can produce high-quality, consistent mold surfaces that meet the required standards for a variety of industries. By reducing the reliance on hand finishing and improving surface consistency, CNC moldmaking has become an essential tool for modern manufacturing processes.

CNC technology plays a critical role in optimizing the flow of materials within molds, which directly impacts the quality and efficiency of the molding process. One of the key factors in successful moldmaking is ensuring that the material flows evenly and efficiently through the mold cavity. CNC machines allow manufacturers to design and refine flow channels and venting systems with high precision. These systems ensure that the material fills the mold evenly, preventing defects such as air pockets or incomplete filling. Additionally, well-designed flow channels reduce the likelihood of excessive flash (excess material that spills over the mold), which can lead to poor part quality and increased post-processing. CNC’s ability to create these features with high accuracy is essential for producing molds that function as intended, delivering consistently high-quality molded parts.

Cooling efficiency is crucial in the moldmaking process, as it impacts both the cycle time and the quality of the final product. CNC technology helps optimize mold cooling by enabling the precise placement of cooling channels within the mold. These channels allow for better heat distribution, ensuring that the material cools at a consistent rate, which reduces warping and improves dimensional accuracy. CNC machines can design complex cooling systems that traditional methods simply cannot achieve, such as conformal cooling channels that follow the contours of the mold, providing even cooling throughout the process. This capability not only enhances the mold's performance but also reduces cycle times, making the overall production process more efficient. The ability to optimize cooling channels using CNC machines leads to faster turnaround times and higher-quality finished parts, which is particularly important in industries where high-volume production and precision are essential.

The integration of CNC technology into moldmaking has significantly transformed the industry over the past few decades. Initially, moldmaking relied on manual techniques, which were both time-consuming and prone to human error. As CNC machines began to gain popularity in the 1960s and 1970s, they revolutionized the production of molds by providing higher precision, faster production speeds, and the ability to create complex shapes. The early adoption of CNC machines in moldmaking was driven by industries requiring high-volume production, such as automotive manufacturing, where the need for consistent quality and rapid production was paramount. As CNC technology evolved, moldmakers began to use more advanced machinery, which enabled them to improve mold design and production processes.

Today, CNC machines used in moldmaking have advanced considerably. Modern multi-axis CNC machines allow for more complex and intricate mold designs, with greater accuracy and efficiency. These machines can move along multiple axes simultaneously, enabling them to create intricate details and curved surfaces that were previously difficult or impossible to achieve. Additionally, the development of advanced tooling has further expanded the capabilities of CNC machines. For example, tools such as ball end mills and wire EDM allow for greater detail and precision in moldmaking. These advancements have made CNC machines an indispensable tool in industries like medical device manufacturing and aerospace, where precision and complex designs are critical.

Looking forward, CNC technology is poised to continue evolving, bringing even greater advancements to moldmaking. One of the most promising areas is the integration of AI and machine learning into CNC operations. These technologies can help optimize tool paths, improve process efficiency, and even predict when maintenance is required, minimizing downtime. Additionally, the use of 3D printing and additive manufacturing in conjunction with CNC machines is expected to further enhance moldmaking capabilities, allowing for the rapid prototyping of mold components and faster design iterations. As CNC technology continues to advance, moldmaking will become even more efficient, precise, and cost-effective, benefiting industries that rely on high-quality molded parts.

Technology | Key Feature | Benefits | Applications |

CNC Milling | Precise mold cavity shaping | High accuracy, fast production | Automotive, consumer goods, medical |

Multi-axis CNC | Multi-axis movement | Complex and detailed mold features | Aerospace, automotive, medical devices |

CNC Turning | Round mold core creation | High-speed production, uniformity | Casting, injection molds |

Wire EDM | Fine details and intricate features | Precision in hard materials, small features | High-detail mold designs, cooling channels |

Tip: These advancements ensure that CNC technology will continue to drive innovation in the moldmaking process, providing manufacturers with the tools they need to meet the growing demands of modern production.

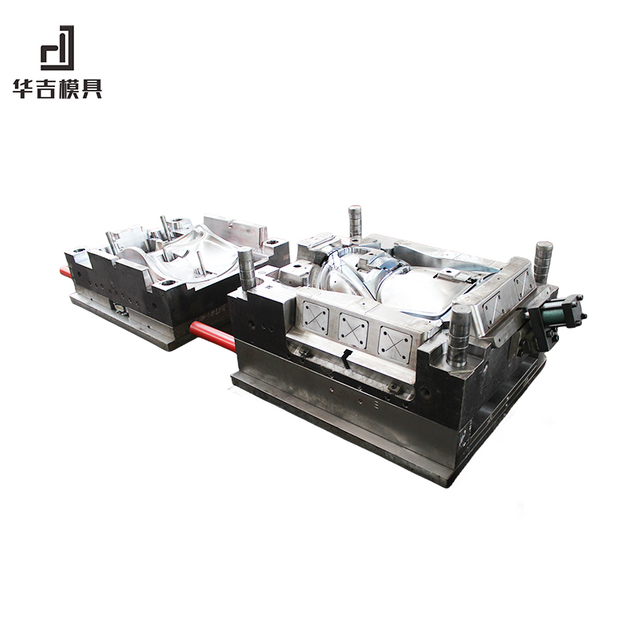

CNC technology plays a crucial role in modern moldmaking, offering significant benefits such as high precision, faster production speeds, and versatility. It enhances mold quality by enabling precise control over design, flow channels, and cooling systems. Manufacturers are encouraged to integrate CNC into their moldmaking processes for improved product quality and reduced production times. Companies like Huajimould offer advanced CNC solutions that can streamline the moldmaking process, ensuring top-tier quality and efficiency in every production run.

A: A CNC mold is a mold created using Computer Numerical Control (CNC) machining, which ensures high precision and intricate designs for mold cavities, cores, and other features.

A: CNC technology enhances the moldmaking process by providing precise control over the design, reducing errors, and speeding up production, resulting in consistent and high-quality molds.

A: CNC in moldmaking increases efficiency, improves precision, and allows for more complex designs, reducing production time and improving the overall quality of molded parts.

A: CNC technology allows for the precise design of cooling channels, which helps optimize cooling efficiency, reduce cycle times, and improve the quality of molded parts.

A: CNC tools, such as ball end mills, help achieve smoother finishes directly on the mold, minimizing the need for additional hand-finishing work.